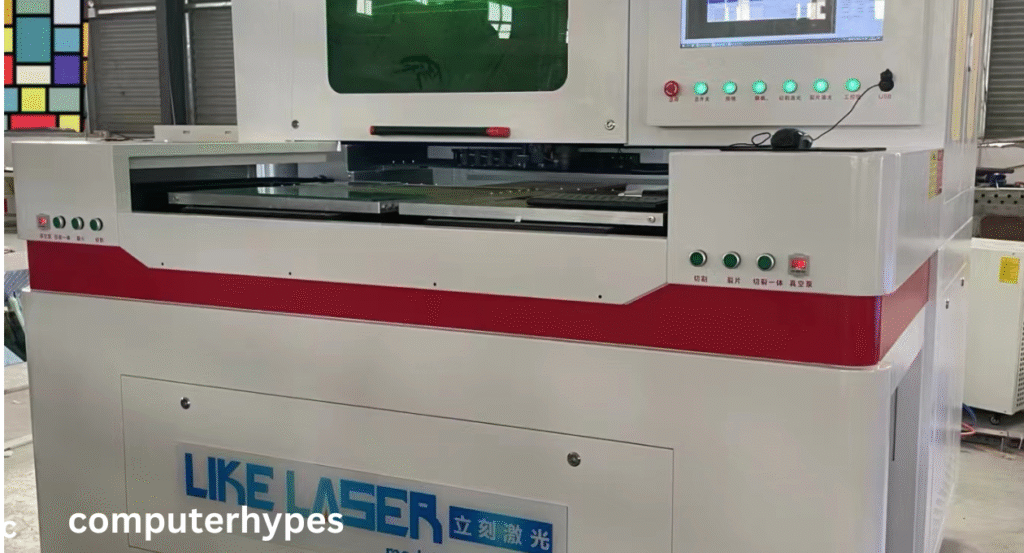

Laser Drilling Machine Precision at Its Best

Introduction to Laser Drilling Machine

Laser drilling machine have revolutionized the way industries approach precision cutting and drilling. Unlike traditional drilling methods that rely on physical force, laser drilling utilizes highly focused beams of light to penetrate through materials with incredible accuracy. This advanced technology is now widely used across various industries, from aerospace to healthcare, because it offers unparalleled precision and efficiency.

click in link Laser Printers Hartford

So, what makes laser drilling so special? To answer that, let’s first understand the basics. A laser drilling machine works by directing a concentrated beam of light onto a material’s surface. The heat from the laser melts, burns, or vaporizes the targeted area, leaving behind a clean and accurate hole. Unlike mechanical drills, which cause wear and tear, laser drilling does not involve direct contact, reducing tool damage and extending lifespan.

The evolution of drilling technology has been significant. In the past, industries relied heavily on mechanical and electrical drilling methods, which were effective but limited in precision. As products became smaller and more complex—especially in electronics and aerospace—the demand for micro-holes and complex patterns grew. Traditional methods could not keep up with the increasing demand for miniaturization, which led to the rise of laser drilling.

Industries today prefer laser drilling over conventional methods for several reasons. First, the accuracy is unmatched—laser drilling can create holes as small as a few microns with precise depth control. Second, it can handle a wide variety of materials, including metals, ceramics, plastics, and composites. Lastly, the speed and efficiency it offers have made it a game-changer in mass production.

In short, laser drilling machines are not just tools; they are enablers of modern technology. They make it possible to create jet engine parts, medical implants, microelectronic circuits, and even renewable energy components with precision that was once unimaginable.

Working Principle of Laser Drilling Machines

The working principle of a laser drilling machine is rooted in the physics of light and heat. At its core, the machine uses a concentrated laser beam, which is directed at the surface of a material. The laser energy is absorbed by the material, causing localized heating. When the temperature exceeds the material’s melting or vaporization point, a hole is formed.

One of the fascinating aspects of laser drilling is its versatility. The process doesn’t depend on mechanical pressure; instead, it relies on the controlled delivery of energy. The duration and intensity of the laser beam can be adjusted to create different types of holes—whether shallow, deep, narrow, or wide. This flexibility is what makes laser drilling suitable for both macro and micro applications.

Different types of lasers are used in drilling, depending on the material and application. For example:

- CO₂ lasers are commonly used for non-metallic materials like plastics, ceramics, and composites.

- Nd:YAG lasers are popular in metal drilling because they can deliver high-intensity beams with precision.

- Fiber lasers are known for their efficiency, long lifespan, and ability to handle both metals and non-metals effectively.

The machine itself is composed of several critical components:

- Laser Source – Generates the high-energy beam.

- Optical System – Directs and focuses the beam onto the material.

- Worktable – Holds the material in place during drilling.

- Cooling System – Prevents overheating of both the laser and the workpiece.

- Control System – Manages the drilling parameters such as pulse duration, intensity, and positioning.

To put it simply, a laser drilling machine functions like a super-precise torch, burning through materials without any physical touch. This non-contact approach minimizes damage to delicate workpieces and makes it ideal for industries that demand perfection.

click in link Laser Printers Hartford

Types of Laser Drilling Processes

Laser drilling isn’t a one-size-fits-all technique. Depending on the requirements, different methods are used to achieve desired results. Let’s break them down:

Single-Pulse Drilling

This process involves delivering a single, powerful pulse of laser energy to create a hole. It’s fast and efficient but mostly suitable for thin materials. Single-pulse drilling is often used in applications where speed matters more than precision depth control.

Percussion Drilling

Here, multiple pulses of laser energy are directed at the same spot. Each pulse removes a small portion of material until the hole reaches the desired depth. This method is widely used in industries like aerospace, where deep and precise holes are required for components like turbine blades.

Trepanning Drilling

Trepanning is used when larger holes are needed. Instead of burning away the entire area, the laser beam moves in a circular path, removing material from the perimeter. This reduces heat buildup and creates cleaner holes, making it ideal for larger and thicker materials.

Helical Drilling

This is one of the most advanced techniques, where the laser beam moves in a spiral path to create high-quality holes with smooth walls. Helical drilling is used in high-precision industries like electronics and medical devices, where even the smallest irregularity can affect performance.

Each of these processes offers unique advantages, and the choice depends on factors like material thickness, required hole size, and industry standards.

Applications of Laser Drilling Machines

Laser drilling machines have found applications across almost every major industry. Let’s look at some of the most significant ones:

Aerospace Industry

In aerospace, precision is everything. Jet engines, for instance, require thousands of tiny cooling holes in turbine blades to withstand extreme temperatures. Laser drilling makes this possible, as it can produce consistent, micro-sized holes with exact positioning.

Medical and Healthcare Industry

Laser drilling is widely used in creating medical implants, surgical instruments, and drug delivery systems. For example, stents used in cardiovascular treatments often have tiny holes drilled with lasers to ensure proper functionality.

Electronics and Semiconductor Industry

As electronic devices continue to shrink, the demand for micro-holes in circuit boards and semiconductors has skyrocketed. Laser drilling enables the production of micro-vias in printed circuit boards (PCBs), essential for high-density electronic components.

Automotive Industry

From fuel injectors to sensor systems, automotive manufacturing relies on laser drilling for accuracy and consistency. It improves performance and efficiency in critical components, directly impacting vehicle safety and fuel economy.

Energy and Power Generation

In renewable energy, such as solar and wind, laser drilling plays a vital role in producing components like solar panels and high-efficiency turbines. It ensures maximum energy capture and durability of the systems.

These applications show how laser drilling machines are not just tools—they are drivers of innovation across industries.

Advantages of Laser Drilling Machines

The popularity of laser drilling machines is not a coincidence; they offer numerous advantages over traditional methods:

Precision and Accuracy

Laser drilling can achieve micron-level precision. Whether it’s drilling a tiny hole in a microchip or a deep hole in a turbine blade, the accuracy remains consistent.

Speed and Efficiency

The process is incredibly fast. Thousands of holes can be drilled within minutes, making it ideal for large-scale industrial applications.

Non-Contact Process

Since there’s no direct contact between the tool and the workpiece, there’s minimal wear and tear. This not only extends machine life but also ensures cleaner and damage-free results.

Versatility in Materials

Laser drilling can handle a wide range of materials—from metals and alloys to plastics and ceramics. This makes it a universal solution across industries.

In essence, laser drilling combines speed, precision, and flexibility, making it one of the most advanced manufacturing technologies available today.

click in link Laser Printers Hartford

faqs

1. What materials can be drilled using a laser drilling machine?

Laser drilling machines are extremely versatile and can handle a wide range of materials, including metals (steel, aluminum, titanium), non-metals (plastics, ceramics, composites), and even delicate materials like glass. The choice of laser type—CO₂, Nd:YAG, or fiber—depends on the specific material and application.

2. How accurate is laser drilling compared to traditional drilling methods?

Laser drilling offers superior accuracy and precision compared to mechanical drilling. It can create holes as small as a few microns with consistent depth and diameter, making it ideal for industries that require high precision, such as aerospace, electronics, and medical device manufacturing.

3. Is laser drilling expensive?

The initial investment in a laser drilling machine is high due to the advanced technology involved. However, it often proves cost-effective in the long run. The speed, efficiency, low maintenance, and extended tool life help companies achieve a better return on investment (ROI), especially in mass production.

4. What industries benefit the most from laser drilling machines?

Several industries rely heavily on laser drilling, including:

- Aerospace (turbine blades, engine components)

- Electronics (micro-vias in PCBs, semiconductor chips)

- Medical (stents, implants, surgical tools)

- Automotive (fuel injectors, sensors)

- Energy (solar panels, wind turbine components)

5. Are laser drilling machines safe to operate?

Yes, but strict safety measures must be followed. Operators need protective eyewear to shield against laser radiation, and machines should be equipped with safety enclosures. Proper training is also crucial to prevent accidents and ensure efficient operation.

Post Comment